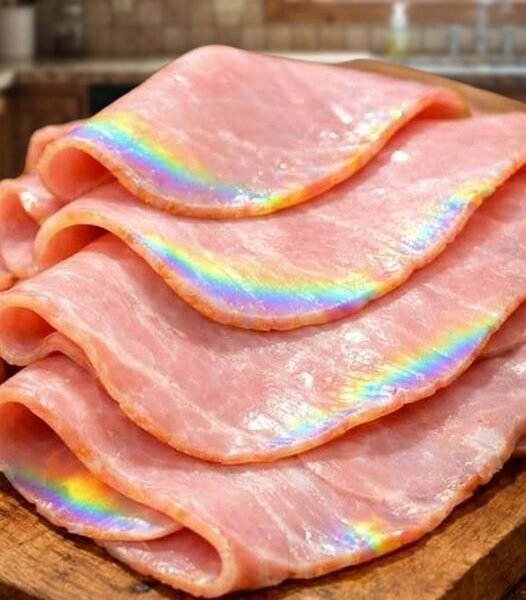

At first glance, it looks like nothing more than a small scrap of metal you might toss away without a second thought. But if you’ve ever picked up a sausage stick and noticed the tiny aluminum ring clipped to one end, you’ve seen a clever detail that most people overlook. This little piece of metal isn’t decoration or leftover packaging — it serves a specific purpose that begins long before the sausage reaches the store shelf. What seems insignificant actually plays a quiet but important role in food preparation, safety, and preservation.

The main function of the aluminum ring is to tightly seal the sausage casing. Sausages are enclosed in natural or synthetic skins that must be closed securely to keep air, moisture, and external contaminants out. By crimping the casing shut, the ring helps preserve flavor and texture while extending shelf life. It also keeps the sausage firm and properly shaped during storage and transportation. Without a secure closure like this, the product could dry out, lose freshness, or become damaged before it ever reaches consumers.

Beyond sealing, the ring also supports efficiency during production and storage. In many facilities, sausages are hung to cure or dry, and the metal loop provides a convenient hanging point that allows air to circulate evenly around the product. This process helps maintain consistent quality and taste. Even at home, some people find the ring useful as a small grip when separating linked sausages without tearing the casing. While these uses are secondary, they show how one small design element can serve multiple practical purposes.

The reason most shoppers never think about the aluminum ring is because it is designed to be discreet. It does its job quietly, without drawing attention, which is exactly what makes it effective. For decades, food manufacturers have relied on these rings because aluminum is lightweight, hygienic, and resistant to rust. The next time you notice that tiny metal clip, it may still look ordinary — but it represents years of refinement in food production methods. Sometimes the smallest details, the ones we barely notice, are the ones that make everyday products work smoothly behind the scenes.